The process flow of compound fertilizer production line can usually be divided into: raw material batching, raw material mixing, raw material granulation, particle drying, particle cooling, particle grading, finished product coating, and finally finished product packaging.

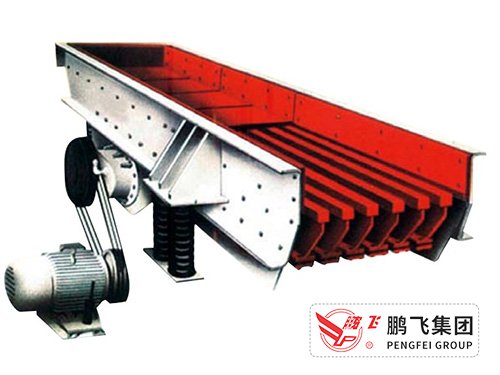

1.Raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, dicalcium phosphate, tricalcium sulfate), potassium chloride (potassium sulfate) and other raw materials are prepared in a certain proportion (based on market demand and soil testing results in various regions).

2.Raw material mixing: Mix the prepared raw materials evenly to increase the overall uniform fertilizer content of the fertilizer particles.

3.Raw material granulation: Send the mixed raw materials into a granulator for granulation (a rotary drum granulator or an extrusion granulator can be used).

4.Particle drying: Send the particles made by the granulator into the dryer to dry the moisture contained in the particles, increase their strength, and facilitate storage.

5.Particle cooling: The temperature of the dried fertilizer particles is too high, making them prone to clumping. After cooling, they are easy to store in bags and transport.

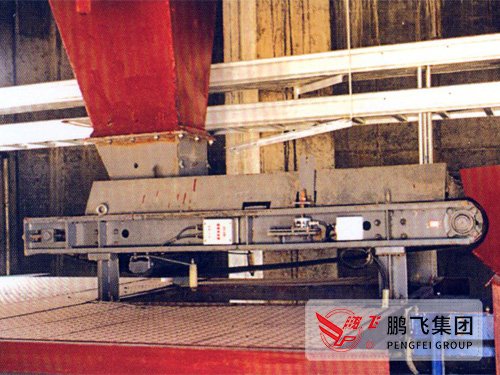

6.Particle grading: Classify the cooled particles, grind and re pelletize the unqualified particles, and sieve out the qualified products.

7.Finished film: Coating qualified products with film to increase the brightness and roundness of particles.

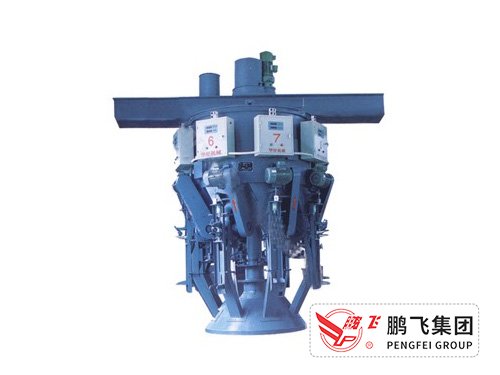

8.Finished product packaging: Pack the particles that have been coated with film, that is, the finished product, into bags and store them in a well ventilated area.